On August 8, the new product launch conference of the LVM3000 series of 2025 Next Vision Tech was held in the form of an online live broadcast, and more than 10,000 partners jointly witnessed the breakthrough progress of domestic 3D vision technology. The LVM3000 series released this time not only demonstrated its "super-standard" strength, but also announced the leap of domestic 3D vision from "seeing clearly" to "seeing through", providing a powerful perception base for intelligent manufacturing.

Eight Years of Deep Cultivation: From Product Iteration to Platform Breakthrough

Wang Yuguo, co-founder of Next Vision Tech, reviewed the company's technological accumulation since its establishment in 2017. The LVM3000 series is not a simple upgrade but a "platform product" for the intelligent manufacturing ecosystem. Its core breakthroughs include:

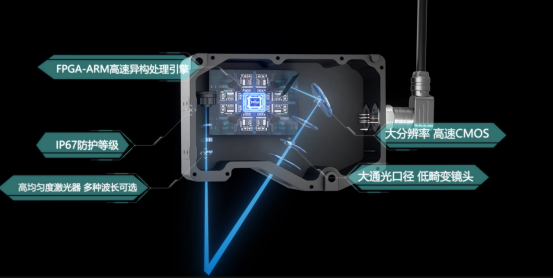

·Hardware Innovation: The new optical path design has achieved a qualitative leap in resolution. The number of single contour points has increased from 4096 to 6500. The small-field camera adopts a folded optical path design, reducing the volume by nearly half and making the installation more flexible. Some models adopt a split structure, supporting users to freely assemble and adapting to complex production line environments.

·Performance breakthrough: The measurement accuracy reaches the sub-micron level, and the frame rate breaks through 6600Hz at the highest, meeting the extreme requirements of high-speed production lines for data update rates.

·Deployment upgrade: Products in the same series maintain a unified installation size. The supporting junction box can greatly simplify the deployment process and achieve "plug and play" in the true sense.

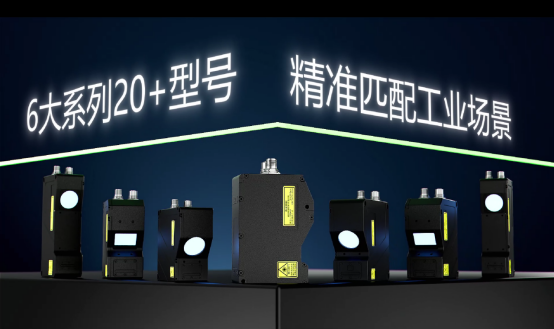

Full-line evolution: Six sub-series cover from general to extreme scenarios

At the press conference, Yuan Xinming, the 3D product manager of Next Vision Tech, elaborated on the six sub-series of the LVM3000 series in detail. Its product matrix covers the entire range from basic detection to extreme performance, precisely matching the increasingly complex requirements of industrial sites:

LVM3000/3300 Series: The "versatile player" for general scenarios, the number of contour points increased by 50% to 3,200 points. The new optical architecture + large aperture design enhance imaging sharpness and anti-interference ability, with the speed increased by up to 50%, suitable for production lines with the vast majority of accuracy and speed requirements.

LVM3400 series: Compared with LVM3000/3300, it has a high-speed acquisition capability with a panoramic depth of 2000Hz and can maintain a stable contour capture effect under dynamic working conditions.

LVM3500 Series: The first choice for high-speed production lines, with a panoramic depth of 2500Hz and capable of obtaining 56,000 contour lines per second in ROI mode; equipped with a 10μm large pixel design and unique optical path anti-reflection suppression technology, it攻克 the difficult problem of detecting high-reflection concave corners of 0.1mm, and is the first choice for scenarios with extremely strict speed requirements such as high-speed detection of new energy battery welds and online quality inspection of micro-components in the 3C industry!

LVM3700 Series: The "Ace" of Sub-micron Detection, with a Super High Resolution of 6,500 Points and a Measurement Accuracy of 3μm - 150μm, Meeting the Ultra-precision Requirements of High-end Manufacturing Such as 3C Electronics. To meet the needs of more high-precision scenarios, larger field-of-view models will be launched successively!

LVM3900 Series: The industry's first ultra-high-speed 4K line laser camera, which can be adapted to large-size 1.6m/s high-speed scanning application scenarios.

LVM3420/3430DL Binocular Single Laser sensor: A "dead - angle - free" sensor with a complex structure, adopting dual - Sensor integration + intelligent complementary algorithm, without on - site stitching and calibration, can restore more than 95% of the occluded area point cloud, and is suitable for the detection of workpieces with depressions and severe occlusions.

In addition to hardware upgrades, the LVM3000 series integrates the intelligent image processing and 3D imaging algorithms independently developed by Next Vision, including core technologies such as surface contour extraction of translucent materials, narrow slit detection in energy maps, and multi-material HDR fusion, ensuring stable imaging in extreme environments such as high reflection, dark areas, and complex surfaces, and reshaping the boundaries of industrial vision performance.

Scene implementation: Four core industries interpret the universality of technology

"The value of technology ultimately needs to be verified on the production line." Shen Jun, the application manager of the 3D product line, shared the applications of the LVM3000 series in core industries:

New energy industry: covering all processes such as pole piece thickness measurement, top cover weld evaluation, and post-weld inspection of Busbar. Through high-precision measurement and real-time data feedback, a production closed-loop of "measurement - feedback - control" is constructed to improve product consistency and safety.

Steel industry: Suitable for the inspection of steel pipes and cold-rolled steel plates, non-contact high-speed full inspection replaces manual inspection, and multi-camera synchronous scanning and one-key calibration simplify deployment.

Tire manufacturing: From the size monitoring of tread extrusion, the detection of joint misalignment in the molding process, to the pattern and character recognition of finished tires, a full-process detection closed-loop is provided to help improve tire consistency and end-user safety performance.

Consumer electronics: Serve dispensing detection (glue width, glue height), re-inspection of assembly gaps, and measurement of complex reflective surfaces with micron-level precision. On the 3C production lines where every inch of space counts, achieve flexible deployment with high-resolution and small-volume designs.

Global Ecology: Empowered by German EVT, jointly build the intelligent perception base

At the press conference, Miao Yu, the General Manager of the China Region of EVT, a German machine vision software company and a global partner of Next Vision Tech, shared a joint solution. The solution combining EVT software and Next vision Tech hardware has been successfully implemented in scenarios such as pantograph detection for high-speed trains, measurement of highway pavement texture, food steak cutting, and weld quality identification.

Miao Yu said, "We have tested 3D cameras of many domestic brands. Next Vision is the one with the most balanced accuracy, speed, and stability among them, and it is a truly worthy domestic representative for long-term cooperation."

Looking Ahead: Re-shaping the Sensing Nerves of Industrial Intelligence

Next Vision Tech driving the transformation of industrial vision from "passive detection" to "active perception" through innovations in hardware, algorithms, and product matrices. As Wang Yuguo said, "Every breakthrough at the micron level is reshaping the boundaries of industrial precision."

Although the press conference has ended, the innovation has just begun. Welcome to scan the official QR code to make an appointment for the prototype test and jointly open a new era of 3D vision.

2025/08/08

2025/08/08