Background knowledge

In the manufacturing of semi-steel tires, chamfer width serves as a critical quality parameter that significantly impacts tire performance and safety. Accurate measurement of this parameter ensures stability and reliability under high-speed driving and complex road conditions. However, traditional measurement methods—including caliper, depth gauge, and probe techniques—have revealed multiple limitations in practical applications, such as low efficiency, limited precision, and susceptibility to human interference, making them inadequate for modern large-scale tire production quality control requirements.

With the development of industrial automation and intelligent technology, 3D industrial cameras have become powerful tools in the field of chamfer width measurement for semi-steel tires, thanks to their unique technical advantages. They provide new solutions to improve measurement accuracy, enhance production efficiency, and ensure product quality.

Camera Selection

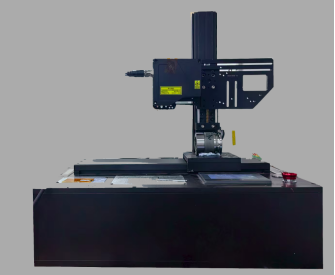

Today, we're excited to showcase the application of the LVM3415 line laser 3D camera, a new addition to Next Vision Tech's LVM3000 series, in the tire industry!

The LVM3415 3D intelligent sensor features a full-frame acquisition rate of 1600Hz, with ROI settings capable of reaching up to 30000Hz. Its 0.1-micron repeatability and high dynamic imaging ensure no detail is missed, making it ideal for high-precision industrial inspection.

surveillance project

·Top chamfer spacing: product radius 25mm, thickness: 11mm

·Precision requirement: 5um

*Image shows the actual product

Detection environment and installation method

·Scanning method: The camera is fixed, and the test sample is scanned along a central straight line.

·Triggering method: Encoders trigger to output stable AB phase difference signals

·Communication mode: TCP/IP Ethernet

Image capture effect

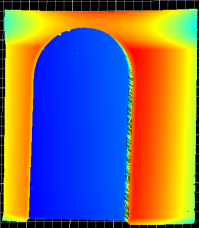

*The image shows a point cloud and depth map

Detection protocol

Figure 1 Figure 2

Figure 1 Figure 2

·The depth image captured by the camera (Figure 1) is used for width detection.

·The product width is measured using tools like preprocessing and linear detection (Figure 2). One product was tested in the experiment, and the tool achieved accurate measurement.

·The test is accurate when repeated more than 10 times.

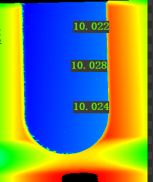

DA

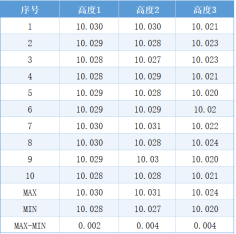

*Measure 10 sets of dynamic data, with a maximum height fluctuation of 0.004mm

Test conclusion

·This solution delivers comprehensive imaging with clear, unobstructed feature images, enabling precise product width measurement using the LVM3415 camera.

After 10 fitting plane tests, measure the distance from the point to the plane. The maximum static repeatability is 0.004mm, meeting customer requirements.

·This camera can reach a maximum speed of 30mm/s

2025/08/15

2025/08/15