Background knowledge

With the trend toward precision and lightweight 3C products, circuit boards as core components have every manufacturing step directly impacting product performance and reliability. The quality control of screw fastening is particularly critical. If screws float, it not only compromises the precision of subsequent component assembly but may also cause severe failures like short circuits or poor contact.

Manual visual inspection is not only inefficient but also subject to light conditions and operator experience. In contrast, 3D industrial cameras, with their high precision, speed, and stability, have become the ideal solution for screw floating height detection in 3C industry circuit boards, providing key technical support for enterprises to achieve cost reduction, quality improvement, and efficiency enhancement.

Camera Selection

Today, we're excited to showcase the LVM3030 linear laser 3D camera, a new addition to Next Vision Tech's LVM3000 series, and its real-world applications in the 3C industry!

The LVM3030 3D smart sensor features a full-frame 600Hz acquisition rate, with ROI settings supporting up to 10,000Hz. It effortlessly handles high-speed dynamic scenes, delivering repeatable precision of 1.6μm and capturing every detail, making it ideal for high-precision industrial inspection.

surveillance project

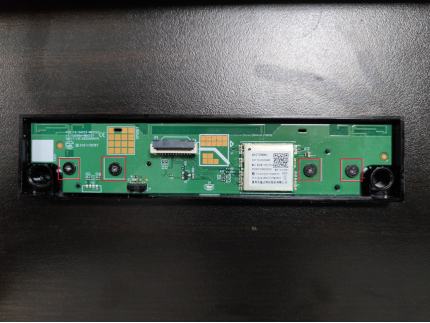

·Measurement requirement: Measure the screw height on the circuit board

·Product dimensions: 140mm x 30mm

·Detection accuracy: 0.02mm

* shows the actual product

Check the environment and installation method.

·Scanning method: The camera is fixed, and the test sample is scanned along a central straight line.

·Triggering method: Encoders trigger to output stable AB phase difference signals

·Communication mode: TCP/IP Ethernet

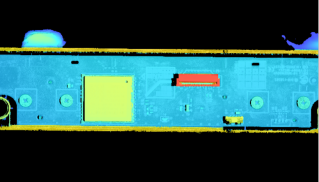

Image capture effect

measured data

*Figure 1

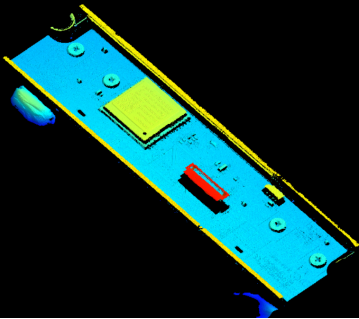

*Figure 2

*Figure 3

*Figure 4

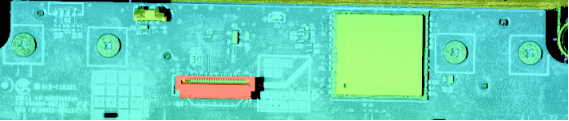

·Depth images captured by the camera (Figure 1)

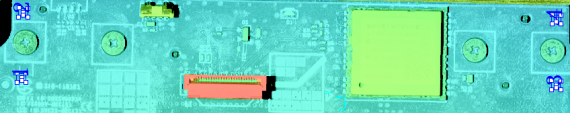

·Get the baseline ROI region (Figure 2)

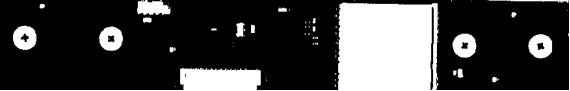

·Image preprocessing: converting depth maps to grayscale (Figure 3)

· Extract screw features through grayscale image segmentation to obtain the measurement ROI area (Figure 4)

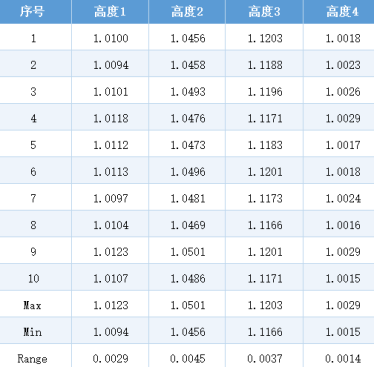

·Calculate the height of each of the four screws separately

DA

static repetitiveness

dynamic repetitiveness

*After 10 tests, both static and dynamic height measurements remained below 0.01mm.

Test conclusion

This solution delivers comprehensive imaging with high-definition feature images. The LVM3030 camera enables precise screw height measurement on product circuit boards, achieving detection accuracy within 0.01mm to meet customer specifications.

·The camera has an X-axis resolution of 30μm, with a maximum testing speed of 45mm/s

·The camera has a maximum line width of 97mm. One scan can fully cover the product

2025/10/24

2025/10/24